Cite 14 Recommendations 30th Aug, 2013 Sarghie. The second and lengthier way uses the Intersect (Knife) mesh operation: Combine two (or more) objects together with Ctrl. Your separate pieces will now be combined, with new geometry created at the intersections, forming one solid mesh. Press Ctrl + Shift + Numpad Enter to apply the operation.

If you do so, press File->Import Mesh and chose the 3mm polygon mesh.stl. Press Ctrl + Numpad +, to perform a union operation.

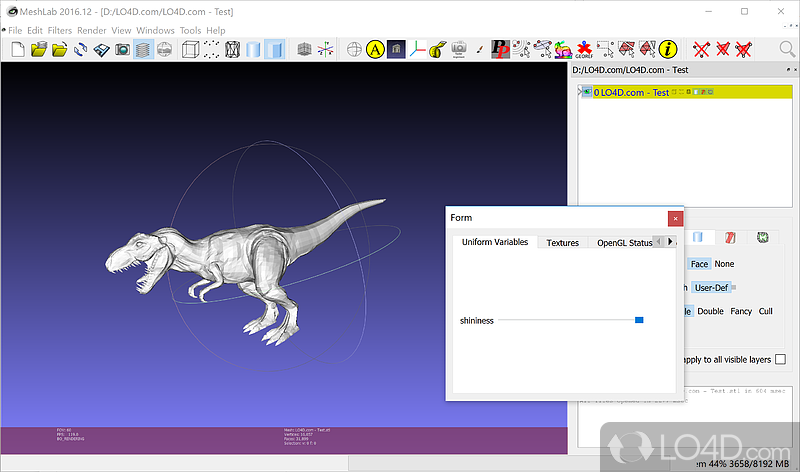

Meshlab create shell software#

Previous versions of Netfabb software were not able to do that. You can use the MeshLab, it's free and does not need particular knowledge. I say that because it will make an overlapping shell STL printable seemingly every time. I would need some advice to find the best method to weld these cracks, which does not change the vertices that are not along them, adding only the geometry needed to close the mesh (or, ideally, to make a weld using the existing edges along the edge). This does not seem to be the same Netfabb repair tool that’s been around in various forms for quite a while now. Luckily David recently pointed out a new STL repair tool that seems to eliminate these problems. There is a big gap between the effect after linking the texture map and the opening with meshlab. and then I generate the texture map through the above method as shown in the figure below: Then I linked the texture map to ue4 as shown below. I have been able to get a very few parts like this sliced properly with Plic3r, but only with careful/tedious tweaking of the underlying geometry. For example, you could scale a 3D design and adjust it to your measurements and then print it with your 3D printer in the appropriate size (scale), etc. Open the y file with meshlab as shown below.

Generally speaking the slicers I use (Craftware, the Prusa version of Slic3r (which I call Plic3r), and Simplif圓D) do strange things when slicing an STL that has overlapping shells. I’ve been dealing with this issue for quite a while now, and what I’ve found out is that different slicing programs handle the same STL file that has overlapping shells quite differently. What we need to do is create an offset of. After the script has been successfully run, the database can be accessed from all Azure services and the allowed IP address range. To do so, we can use the fantastic software MeshLab, which is ideal for this kind of task. The problem with 3D printing objects with intersecting/overlapping shells is indeed a vexing one. This Azure CLI script example creates a single database in Azure SQL Database and configures a server-level firewall rule.

0 kommentar(er)

0 kommentar(er)